Entry Level Production & Logistics

(VETERAN CARE’S MAP)

Manufacturing Apprenticeship Program Certification Training

Introduction To Manufacturing

Manufacturing Processes & Production:

· Learn the names and uses of Manufacturing Processes

· Learn the materials and equipment used in Continuous Flow, Custom Manufacturing, Fixed Production and Production Line Manufacturing

· Read Entry Level CAD Designs

· Demonstrate production line operations

· Demonstrate Work Flow Planning and Control

· Demonstrate ability to read and work with work orders and documentations

· Use CAD Drawings in the production line

· Follow Work Orders

· Demonstrate proper handling of machinery

· Develop efficiency in production tasks

· Perform Quality Checks on Products and Parts.

Manufacturing Roles and Responsibilities

· Explain the Production Line Roles of Assembly, Maintenance, Logistics, Supervisors

· Explain the Logistics of Product from Production to Shipping

· Demonstrate Proper Work Procedures in Production and Logistics

· Self Monitor Production and Efficiency

· Document Product Production Properly

· Understand and Follow Company’s Policy

· Be Able to Explain Company Vision and Mission

Manufacturing Tools and Materials

Common Tools, Usage and Safety:

· Proper Use of Gauges

· Ability to Read and Interpret Gauges

· Proper Usage of Measurement Tools: Geometric Dimensioning and Tolerancing, Caliper

· Understanding American and Metric Measurements

· Demonstrate Basic Tool Knowledge and Proper Usage: Tape Measure, Basic Wrenches, Pliers, Gauges

Proper Handling of Products

· Demonstrate OSHA Safety Compliance with Chemicals, Hazardous Materials

· Properly Store, Use and Apply Hazardous Materials

· Wear Proper PPE When Handling Hazardous Materials

· Ability to Read Labels and Explain Them on Hazardous, Flammable or Explosive Materials

Mathematical Concepts in Manufacturing

· Demonstrate Knowledge of Order of Operations

· Demonstrate Problem Solving Capabilities

· Explain How Fractions Apply in Production and Machinery Operation

· Read and Interpret Symbols in Relation to CAD, Blue Prints, Engineering Drawings

Current Manufacturing Systems

Lean Manufacturing:

5S Concepts: Sort, Simplify, Sweep, Standardize, Self-Discipline, Benefits of 5S

Just in Time Concepts:

Sales, Design, Procurement, Nesting, Production, Shipping

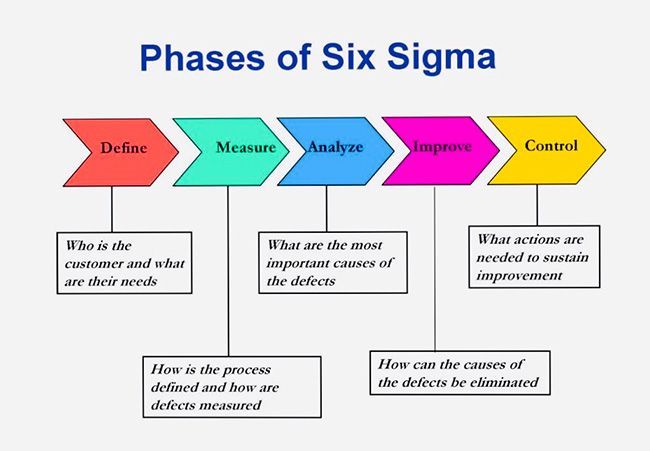

Six Sigma:

DMAIC, Project Definition, Process Mapping, Concepts of Waste, Value Addition, Data Collection, Kaizen, Process Control

Team Work in Manufacturing:

Commitment, Process, Evaluation

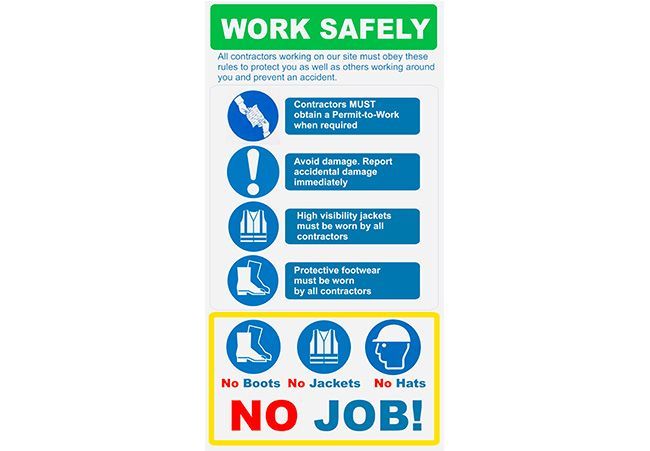

Safety and Maintenance Measures:

· Demonstrate OSHA Safety compliance

· Wear proper PPE

· Identify Safe and Unsafe Conditions

· Demonstrate Knowledge on Safe Storage of Hazardous Materials

· Explain Fire and Electrical Safety as it applies to production and logistics

· Demonstrate Forklift Safety Measures in Operation and in Working Around Forklifts

· Read and Understand Chemical Hazard Labels

· Report Safety Concerns for Machinery, Production and Logistics

· Demonstrate Safety Measures with Proper Housekeeping, Waste Reduction and Communication

· Practice Safe Machinery and Tool Usage

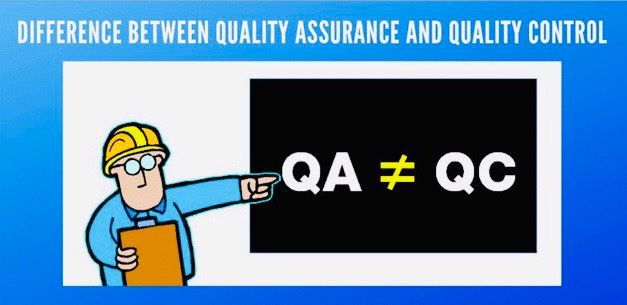

Quality Standards

Quality Standards and Measurements

· Understand Quality Control and Audits

· Importance of Machinery Inspections, Calibrations and Data Collection

· Inspect Materials, Products and Process

· Understand Company’s Procedures and Demonstrate This at Work

· Understand the Production Process and How Each Area is Inter -related

· Proper Use of Inspection Tools

· Blueprint Reading

· Basic Measurements

Green Manufacturing Concepts & Applications

· Participate in Workforce Training

· Implement Green / Environmental Policies

· Maintain a Clean, Clutter Free Work Place

· Reduce Waste

· Demonstrate Energy Efficient Production in Terms of Time and Material

· Be Conscientious of Personal Waste / Trash

Logistics of Manufacturing

· Perform Quality Checks on Products and Parts

· Package Finished Products and Prepare for Shipment

· Understand Proper Labeling Procedures for Shipping

· Review Work Orders and Blue Prints to Ensure Work is Performed According to Specifications

· Maintain Inventory of Shipping Needs, Materials, Inventory for Production

· Understand Proper Ordering of Materials Needed and Projected Materials for Upcoming Orders

· Operate Forklifts and Shipping Machinery